News

Turnkey construction of Hexcel plant in Isère department

On behalf of American group Hexcel, a world leader in carbon fibre manufacturing, the engineering consultancy Fluor has selected Bouygues Energies & Services and Bouygues Bâtiment Sud-Est, both Bouygues Construction subsidiaries, as partners to build Hexcel’s new latest-generation production site in Roussillon, in the Isère department. Industrial engineering specialist Bouygues Energies & Services, lead firm of the consortium, has just signed an additional contract, alongside Colas piping subsidiary SPAC, to carry out the technical packages. The studies and civil works are already under way, with the project set to be delivered in August 2017.

“This new turnkey construction contract for an industrial site is the first of its size for Bouygues Construction. It confirms the group’s ability to apply all of its skill sets to complex, large-scale projects for major industrial clients,” points out Jean-Christophe Perraud, Bouygues Energies & Services CEO.

The new plant, which is designed to meet growing demand for composites in the aeronautics sector and increasing global demand for carbon fibre, will cover a 15-hectare site at the Roches-Roussillon OSIRIS facility to the south of Lyon.

Bouygues Bâtiment Sud-Est Est is to design and carry out the civil works, core and shell packages and architectural trades. Bouygues Energies & Services will carry out the electrical engineering, HVAC engineering, and process piping together with SPAC, and will install the client's process facilities. The company is also involved in supplying the process facilities, thus supporting Hexcel in a key aspect of its industrial strategy.

Building on the relationship of trust established over more than two years and on a first project involving the multi-technical design of the plant at the end of 2014, Hexcel has extended its collaboration with the consortium by mutual agreement. The aim is to make technical adjustments to the processes so as to bring them into line with French standards, while ensuring the whole-life cost is kept under control. The project feasibility studies and subsequent technical studies, driven by Bouygues Energies & Services and Bouygues Bâtiment Sud-Est, were conducted with engineering consultancy Fluor.

Civil works got under way in August 2015, and 300 employees will be involved at peak periods in both the core and shell and process works. The project will represent around 250,000 hours for the civil works and core and shell aspects, and over 300,000 hours of work for the technical packages.

The consortium has set up specific measures to meet the client's expectations with regard to safety and performance. Extensive quality checks are implemented during the design, construction and commissioning phases. Moreover, all of the works phases are subject to approvals and daily risk assessments to ensure compliance with the zero-accident policy shared by the client and Bouygues Construction. Specific training programmes (chemical hazards, working in confined spaces, etc.) are also run for all stakeholders, whether Bouygues Construction staff or subcontractors.

Latest news

Find all the topics that make Bouygues Energies & Services news: projects, innovations, public and client events, partnerships, press releases ...

-

-

-

-

-

-

- Our UK team has been selected by VIRTUSfor the turnkey delivery of its LONDON7

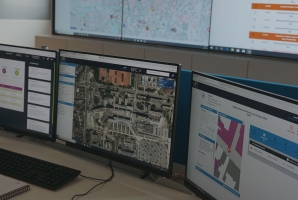

- After 1 year of work, the connected control centre of the OnDijon project was unveiled

- The Top Employers Institute acknowledges the quality of the company’s working conditions and its HR policies.

- With Sun'R we have combined our skills to support Lamagistère in its energy transition.

- Axione becomes the 86th member of the altnet cooperative.

- Our goal : being innovative together.

- SIRO announces investment with joint venture to connect 10 towns to Its gigabit network

- Signing of a new contract with Equis, the first regional developer of renewable energies

- An exemplary project combining technical challenges, energy development and local involvement

- Creation and animation of dynamic trail of light showcasing 39 important sites

- Five buildings comprising several operating theatres and 250 beds